Taking a vacation was always accompanied by a tinge of sadness and frustration for Sukanya Dikshit, founder and CEO of Phabio Enterprises. The plastic waste lying around marred the beauty of the location. While most of us simply leave with a feeling of frustration, Sukanya decided to do something about it.

In Part 2 of our Sustainable Packaging series, we showcase Phabio Enterprises, led by Sukanya Dikshit.

Armed with a Masters degree in biotechnology from Indian Institute of Technology, Rourkee, Sukanya began researching on sustainable alternatives to plastic. After much experimentation, she selected beer waste and food waste for in-depth research. The outcome is phenomenal. A natural plastic with properties similar to polypropylene (or fossil-fuel based plastic), except for one key difference. It is biodegradable. And it does not need industrial facilities to biodegrade. It biodegrades at room temperature and even in a marine environment. Known as Polyhydroxyalkanoates (or PHA in short), these polymers are synthesized naturally in nature. These polyesters are stored as energy in the cells of certain microorganisms and their biodegradable nature has found many applications in the biomedical sector[1].

[1] https://www.sciencedirect.com/science/article/abs/pii/S0964830517300276

Phabio was born!

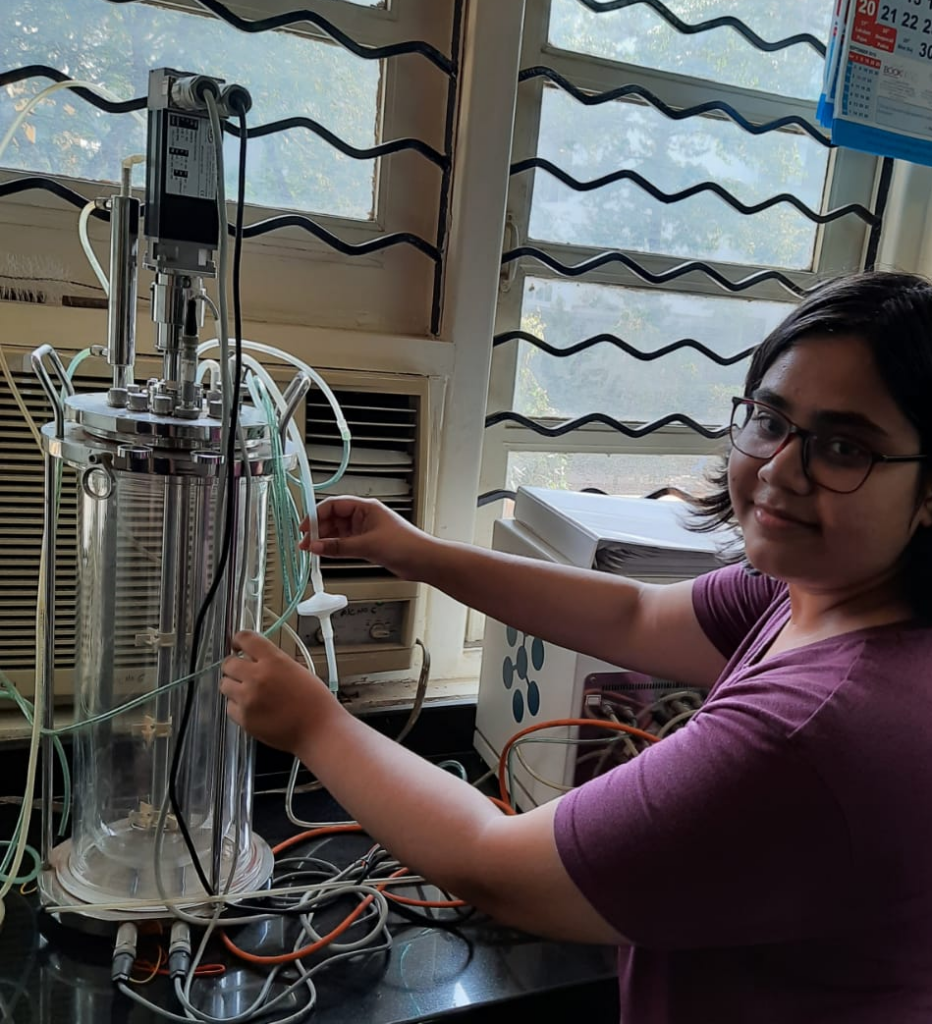

Sukanya and her team experimented further with the extraction and further processing of certain PHAs from food waste. Their goal was to reduce the cost of extraction, eliminate the use of chemicals and use minimal or no water in the process.

They wanted to create a product that could be fed into the existing machines that make plastic products. Nine months of research later, Sukanya and her team had their eureka moment. They use certain types of bacteria to feed upon food (or beer) waste, which in turn store the biopolyester in the form of oil. This oil is extracted and converted into a powder. This is further formulated into a granulated form and stored in the form of pellets. These pellets can be used by any plastic manufacturing facility to make plastic bags. The process is completely chemical-free and, if they are using beer waste, is a zero-water process. The magic material that is derived from this patent-pending process is a combination of short-chain and medium-chain PHA, known as a novel SCL MCL co-polymer.

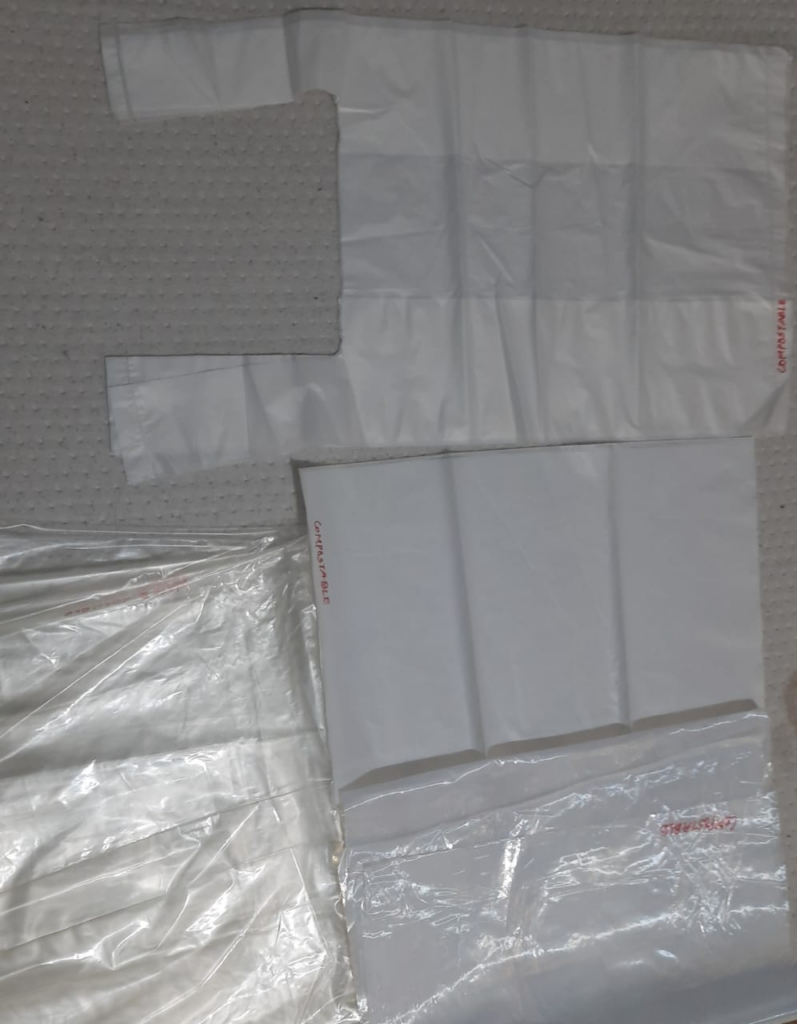

Plastic bags derived from these pellets have gone through rigorous testing and have been found to be able to degrade under room temperature conditions in soil and sea within 120 days!

Further, the degraded product does not leave behind harmful chemicals, since it is a biologically derived material. Phabio is in the process of obtaining the required certifications such as ISO, ASTM D6400 and EN13242 for compostability and biodegradability.

Industry Connects

Phabio is now working to partner with several large-scale industries to use their waste and make plastic. One such company is Anheuser-Busch, America’s largest brewery. Having just a small manufacturing facility of their own right now, they are looking to set up a bigger facility through some partnerships. A 1000 tons per year facility would cost around $5 million with a break-even time of 12 months. Currently, there is a high demand for their product in Europe, where they have voted to ban single-use plastic. The law, that will come into force in 2021, will impact all countries in the European Union[1].

Awards

1. Selected as the top innovator among 6400 innovations in the BIG-IDEA SUMMIT 2018, Held in Mumbai.

2. Selected and successfully completed the MENTORING BY ALUMNI program by Desai Sethi Center, IIT Bombay,2019 (50000 INR grant)

3. Won the first prize among 700 cleantech startups globally in the UK Cleantech challenge organized by London Business School,2019 (10000 GBP grant)

4. Selected and successfully completed the Pre-incubation program by Desai Sethi Center, IIT Bombay, 2019 (2,00,000 INR grant)

5. Selected into YES-DELFT validator program at TU DELFT, Amsterdam, 2019 (sponsored trip)

6. Selected into top 15 startups globally in the Blue Bio Value acceleration program, Lisbon, Portugal, 2019 (7,500 EUROS Sponsorship)

7. Selected as top 9 innovators in the South Asian Region for the FASHION FOR GOOD program, 2020

Meet the Team

Phabio is a small, yet impactful, 5-member team. Sukanya Dikshit, who has a Masters in Biotechnology from IIT Roorkee and is a IIT Bombay PhD dropout, is the technology person and founder of Phabio. Anmol Bansal is the co-founder of Phabio and the Head of Business Development. Rishabh Gupta is the third co founder and head of operations. They also have a couple of employees working with them. The core team is based in Kanpur, India.

The Way Forward

Phabio is continuing research on reducing the cost of extracting the bioplastic. In addition, they are experimenting with using other types of waste such as agricultural waste in their process. Since their pellets can only make plastic bags as of now, they are continuing R&D to make material that can be used to manufacture plastic bottles.

A long road ahead, but filled with meaning and purpose. We wish Sukanya and her team all the best in this journey.

[1] https://www.theguardian.com/environment/2019/mar/27/the-last-straw-european-parliament-votes-to-ban-single-use-plastics#:~:text=The%20European%20parliament%20has%20voted,in%20all%20EU%20member%20states.