The Need for Sustainable Packaging

Ever since plastic was introduced in the market around four decades ago, it has found its way into every aspect of human life. Over the years, we have experienced the benefits and pains of this so-called “magic” material. There are any number of scary facts about plastic that has compelled eco-warriors to wage a war against plastics. Both industry and civil society have begun to take notice and are slowly but surely instituting a change. Researchers in the area have been working on various forms of bio-plastics – plastics made from plants such as corn and sugarcane. However, in order for these bioplastics to be degradable in a reasonable length of time, industrial composting facilities are necessary where the bio-plastics are heated to a high temperature[1]. In some parts of the world, such as India, this is unthinkable. So where does that leave us? Bio-plastics that exist today still take the same amount of time as regular plastic to degrade[2]. If they degrade at all, they form microplastics that are even more damaging than plastics, especially to marine animals.

There is a need to find sustainable alternatives to this ubiquitous material called plastic. Truly sustainable from cradle to grave. We also believe there cannot be just one solution that fits all – the answer is in the implementation of multiple solutions. In this series, we would like to showcase some enterprising startups who are aiming to do exactly that – create sustainable alternatives to plastic. Part 1 of this series is dedicated to a company call Dhriti Bio Solutions.

DHRITI BIO SOLUTIONS

A chance visit to an expo made researchers Dr. Anudeep Sandamudi and Shiva Subramanian think hard about the reality of plastics today and the so-called bioplastics available in the market. Delving deep into the issue, they decided they had to do something about this ubiquitous material.

They worked for 4 long years to come up with a game changing alternative to plastics. They started this quest with some basic goals –

The material needed to retain the useful aspects of plastics, such as being water resistant

The material needed to be truly biodegradable without generating micro-plastics

The raw materials and the manufacturing process needed to be sustainable

The manufacturing process should be able to utilize the existing machinery used to make plastic

Calling themselves as an R&D company Dhriti Bio Solutions or DBS, R&D wing of PHD Pvt Ltd Bangalore-, they set off on their quest. Today, they have come up with a product that checks off the impressive list of goals they started with.

[1] https://www.nationalgeographic.com/environment/2018/11/are-bioplastics-made-from-plants-better-for-environment-ocean-plastic/

[2] https://scroll.in/article/880067/as-bioplastics-get-popular-in-india-a-more-genuine-green-choice-is-to-boot-out-plastic-altogether

The product

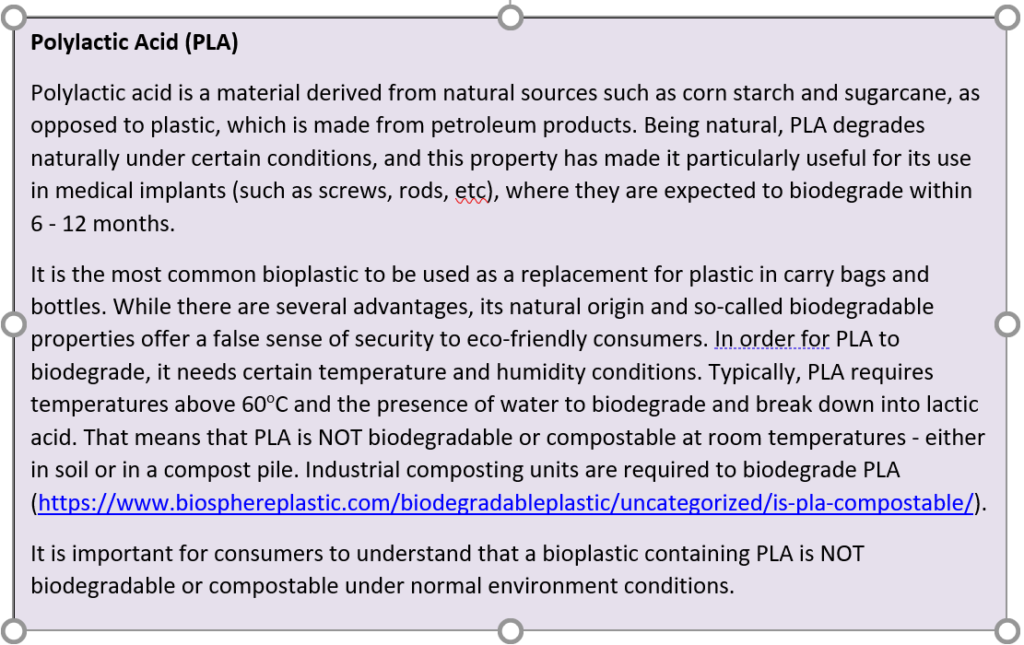

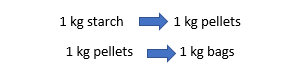

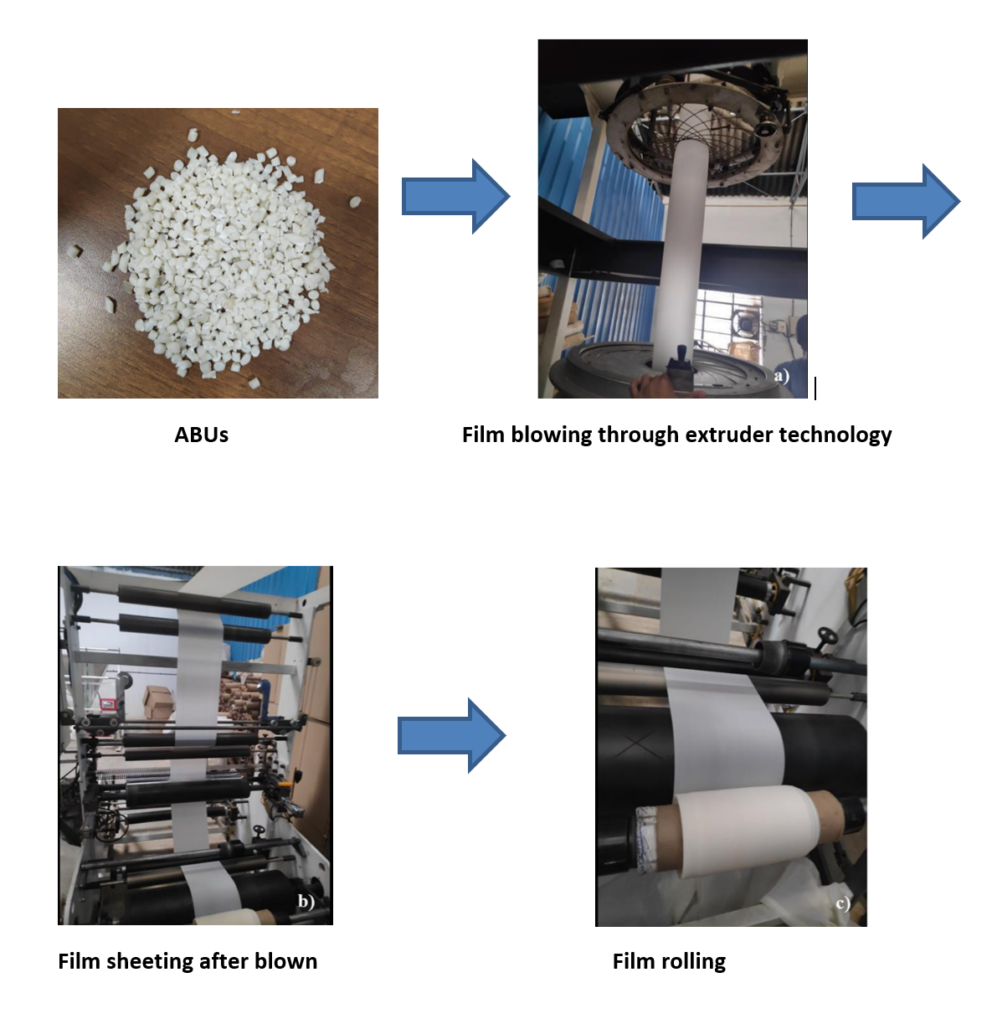

Known as Adaptable Biodegradable Unit (ABU), this product is made from a plant extract and is starch based, such as tapioca starch and corn starch. This starch does not contain PLA (Poly-lactic acid). And why is that a good thing? Refer to the inset. The starch that DBS uses is procured commercially and it then undergoes special processing in their facility. The final product is in the form of pellets that can be used as a raw material at any plastic manufacturing facility. In essence, these pellets can be rolled and extruded and made into products that replace single use plastic, including —

bags and bottles. Most importantly, the entire process has a zero-waste and zero-water footprint! For instance,

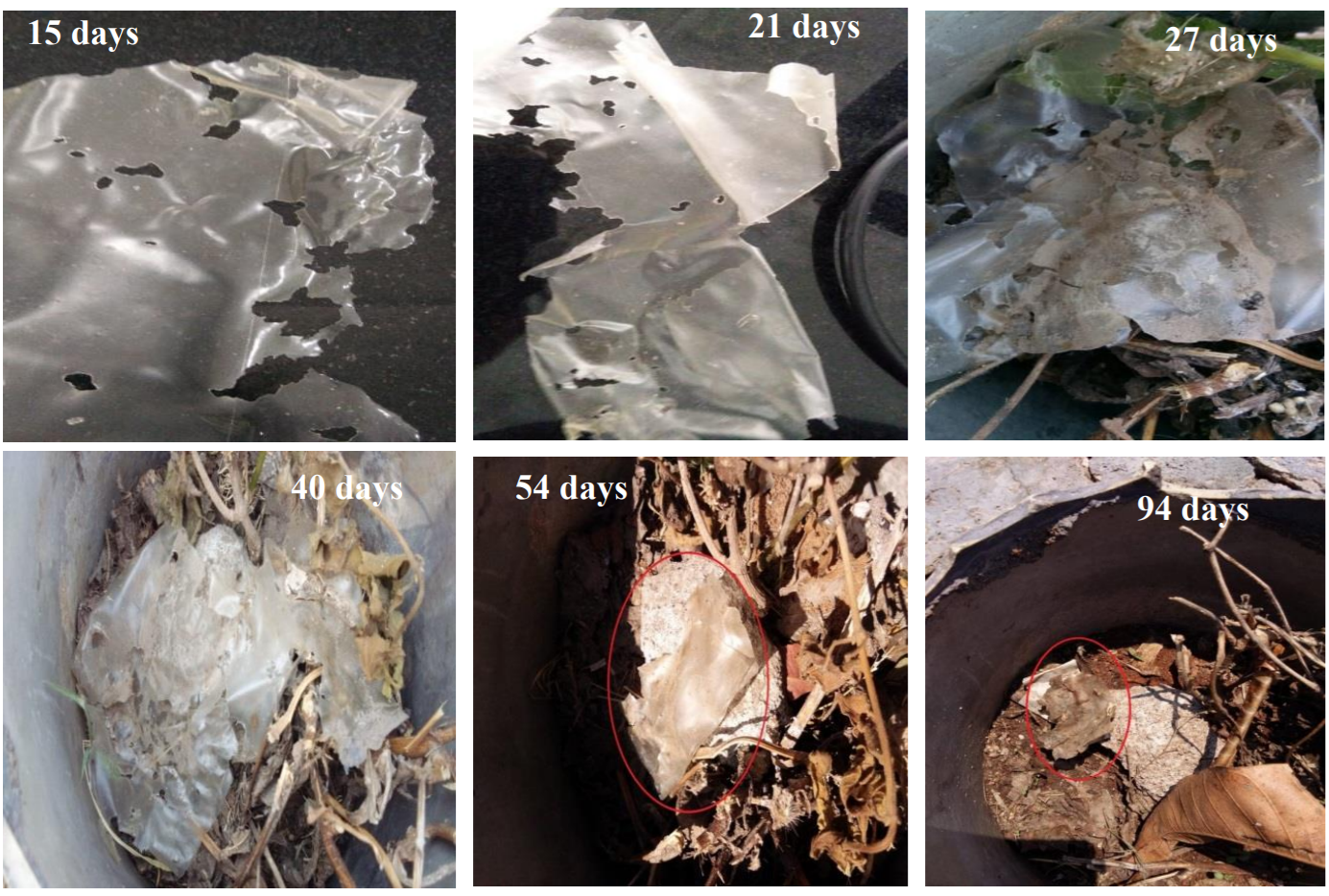

The material that evolves from the ABUs is water resistant, sealable like regular plastic, heat resistant, and has high tensile strength. It has also been tested for food safety. On the shelf, its life is 2 years. Once discarded, it decomposes in 4-6 months (cover image), as per the garden compost studies conducted at at the Central Food Technological Research Institute (CFTRI) in Mysore. Industrial composting has also been tested as per the ISO standard for Specifications for Compostable Plastics – ISO 17088.

There is more…

Not wanting to stop their exploration there, Dr. Anudeep and team started working on ways to replace multiple use plastic. Experimenting with the raw material, they tried blending waste materials into the starch to try and kill two birds with one stone. Using 30% waste material (such as coffee waste, arecenut waste and banana waste), they designed ABUs that could be used to make multi-use cups, cutlery, bowls, trays and boxes. The prototype was developed by encapsulating the food waste with the ABUs. These protypes were tested for strength, shape, rigidity and flexibility. The ensuing product has great potential to replace all single use cups and cutlery with a much more sustainable product.

What next?

Incubated at CFTRI, Mysore., DBS is now seeking to work with plastic manufacturing facilities to supply their ABUs. Currently, there is a potential market in Spain. Simultaneously, they are setting up a manufacturing plant in Bangalore to make ABUs. They plan to establish manufacturing clusters all around the globe to serve the environment.

The innovation, however, continues. They are looking for ways to make the ABUs 50% cheaper. Being hard-core researchers, they are keen to bring out this innovative product at the best cost possible.

We believe this has a huge potential in changing the game where plastics are concerned. Today, industry and citizens alike are looking for a reliable replacement for plastic that is truly sustainable. We wish DBS all the best in creating and scaling this venture. We encourage them and similar startups to apply for the Beyond the Bag Challenge.

More information on Dhriti Bio Solutions is available at http://dhritibiosolutions.com/